www.ingersollrand.vn

KINH DOANH BƠM MÀNG ARO VÀ MÁY NÉN KHÍ INGERSOLLRAND

Email: info@ingersollrand.vn Điện Thoại : 0946 030 301

The purchase price of a traditional diaphragm pump is the smallest piece of the total pump cost-of-ownership pie. There are downtime costs, energy costs, parts costs and labor costs to consider as well. Add all these up and you’re dealing with a sizeable financial commitment that gets tougher to swallow with each passing quarter. With EXP, you can slice the total cost-ofownership pie down to a much more digestible size. This is what “Solutionizing” is all about; providing smart products that not only demonstrate superior performance, but earn their keep while they’re at it.

EXP Reliability |

ProductivityMaximized flow rates + Minimized pulsation and air consumption = Maximum Performance |

|

VersatilityMultiple porting options available along with interface options allow you to customize this pump specifically to your OEM application. |

|

ReliabilityLube Free Patented Differential Valve both on Major air valve and SimulShift (Pilot Valve) provides reliable Worry Free Operation – Fluid On demand every time. |

|

Environmentally SoundBolted Construction in conjunction with a wide range of material options provides maximum chemical and leak resistance. |

|

ServiceabilityModular Construction, reduced parts count and simple to use repair kits will minimize repair time and cost. |

|

Unbalanced valve design eliminates valve centering and pump stall-out even under low air inlet pressures.

| Diaphragm has pushed actuator pin (B) and Simul-Shift Valve (A) to the right. | |

| 1.) | Compressed Air (red) pneumatically holds the Simul-Shift Valve (A) and the Major Air Valve (C) in position. Large ends of the Simul-Shift Valve (A) and Major Air Valve (C) are vented to exhaust |

| 2.) | The left Quick Dump Check (D) blocks the exhaust port. Compressed air flows around Quick Dump Check (D) into the left diaphragm chamber. |

| 3.) | The right Quick Dump Check (E) lifts to open the exhaust port and allows cold, wet exhaust air (blue) from the right diaphragm chamber to flow into the expansion chamber, while diverting cold, wet exhaust air (blue) from the Major Air Valve. |

| 4.) | Diaphragm reverses direction (C) |

| 1.) | The diaphragm pushes the right Actuator Pin (B) mechanically moving the Simul-Shift Valve (A) to the left. |

| 2.) | Compressed air flows to the large side of the Simul-Shift Valve, pneumatically moving the valve to the position shown. |

| 3.) | Compressed air also flows to the large end of the Major Air Valve (C), pneumatically shifting it to the left. |

| 4.) | Shift of the Major Air Valve (C) results in an air pressure differential between the Quick Dump Checks (D&E) - causing the Quick Dump Checks to shift position. |

| 5.) | The right Quick Dump Check (E) blocks the exhaust port. Compressed air (red) flows around the Quick Dump Check into the right diaphragm chamber |

| 6.) | The left Quick Dump Check (D) lifts to open the exhaust port and allows cold, wet exhaust air (blue) from the left diaphragm chamber to flow into the expansion chamber, while diverting cold, wet exhaust air (blue) from the Major Air Valve (C). |

| 7.) | Diaphragms reverse direction |

From its simple beginnings as a utility dewatering / trash pump, through its various phases of design evolution, the diaphragm pump has been a favorite with process professionals everywhere. Why? Simplicity. The ARO EXP design team has taken this fundamental feature and

engineered efficiency, compatibility and economy into every aspect of the new EXP Diaphragm Pump. Economy in fewer repair parts and labor. Economy in saved energy. Economy in superior performance. Do you want to reduce pump downtime while boosting production? Here it is.

|

|||||

| Models: | 3/8" | 1/2" | 1" | 1-1/2" | 2" |

| Maximum Flow GPM (LPM) |

10.6 (40.1) |

14.4 (54.5) |

53 (200) |

123 (465) |

184 (696) |

|

Maximum Discharge Pressure PSI (BAR) |

100 (6.9) |

100 (6.9) |

120 (8.3) |

120 (8.3) |

120 (8.3) |

|

Fluid Ports Inlet/Outlet (BSP) |

3/8 - 18 N.P.T.F. - 1 Rp 3/8(3/8-19 BSP) Parallel (Side or Center) |

1/2 - 18 N.P.T.F. - 1 Rp 1/2(1/2-14 BSP) Parallel (Side or Center) |

1" ANSI/DIN Flange (Side or Center) 1 - 11-1/2" NPT Rp 1(1-11 BSP) (Center Discharge) |

1-1/2" ANSI/DIN Flange (Side or Center) |

ANSI/DIN Flange (Side Discharge) |

|

Materials of Construction |

Acetal Polypropylene PVDF |

Acetal Polypropylene PVDF |

Polypropylene PVDF |

Polypropylene PVDF |

Polypropylene PVDF |

| Pump Weight lbs (Kg.) |

4.16 (1.89) Acetal Single Port 4.26 (1.93) Acetal Multi Port 4.50 (2.04) PVDF Single Por 4.62 (2.10) PVDF Multi Port 3.44 (1.56) Poly Single Port 3.55 (1.59) Poly Multi Port |

6.28 (2.85) 6.67 (3.03) 6.78 (3.08) 7.24 (3.28) 5.21 (2.36) 5.44 (2.47) |

19.35 (8.78) Poly Threaded 19.59 (8.89) Poly Center Port 19.87 (9.01) Poly Side Port 25.83 (11.72) PVDF Threaded 26.72 (12.12) PVDF Center Port 27.15 (12.32) PVDF Side Port |

42.60 (19.32) Poly Side Port 63.94 (29.0) PVDF Side Port 42.30 (19.19) Poly Center Port 55.94 (25.37) PVDF Center Port |

85.3 (38.7) Poly 110.9 (50.3) PVDF |

| Maximum Solids inches (mm) |

1/16" (1.6) | 3/32" (2.4) | 1/8" (3.2) | 1/4" (6.4) | 1/4" (6.4) |

| Maximum Dry Suction Lift ft (m) |

8.5 (2.6) (PTFE fitted) |

7.9 (2.4) (PTFE fitted) |

19 (5.7) | 14 (4.2) | 14 (4.2) |

| Recommended Filter/Regulator Air Line Kit |

P29122-600 66073-1 |

P29122-600 66073-1 |

P29221-610 66073-2 |

P29241-610 66084-1 |

P29351-600 66109 |

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 10.6 (40.1) |

| Displacement per cycle Gallons (Liters): | 0.022 (.083) |

| Air Inlet (Female): | 1/4 - 18 P.T.F. SAE Short |

| Fluid Inlet: | 3/8 - 18 N.P.T.F. - 1 (side or center) Rp 3/8 (3/8 - 19 BSP side or center) |

| Fluid Outlet: | 3/8 - 18 N.P.T.F. - 1 (side)

Rp 3/8 (3/8 - 19 BSP side) |

| Max. operating pressure psi (bar): | 100 (6.9) |

| Suspended solids max. dia. in. (mm): | 1/16" (1.6) |

| Weight lbs (kg): |

PD03P-XDS-XXX 4.16 (1.89) PD03P-XES-XXX 4.26 (1.93) PD03P-XKS-XXX 4.50 (2.04) PD03P-XLS-XXX 4.62 (2.10) PD03P-XPS-XXX 3.44 (1.56) PD03P-XRS-XXX 3.55 (1.59) |

| Maximum dry suction lift ft (m): | 8.5 (2.6) PTFE fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 72.7 |

| A | 3/8 -18 N.P.T.F.-1 |

| B | Rp 3/8 (3/8 - 19 BSP) |

| D | Groundable Acetal (Single Port) |

| E | Groundable Acetal (Multiple Port) |

| K | PVDF (Single Port) |

| L | PVDF (Multiple Port) |

| P | Polypropylene (Single Port) |

| R | Polypropylene (Multiple Port) |

| D | Acetal |

| K | PVDF |

| P | Polypropylene |

| S | Stainless Steel |

| A | Santoprene® |

| C | Hytrel® |

| S | Stainless Steel |

| T | PTFE |

| V | Viton® |

| A | Santoprene |

| C | Hytrel |

| T | PTFE / Santoprene |

| V | Viton |

Air Line Connection

Kit 66073-1

PEO3P-APS-PAA -AOS

with 637442-1 kit

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 14.4 (54.5) |

| Displacement per cycle Gallons (Liters): | 0.039 (.15) |

| Air Inlet (Female): | 1/4 -18 P.T.F. SAE SHORT |

| Fluid Inlet/Outlet: |

1/2 - 14 N.P.T.F. - 1 1/2 -14 BSP, parallel |

| Max. operating pressure psi (bar): | 100 (6.9) |

| Suspended solids max. dia. in. (mm): | 3/32" (2.4) |

| Weight lbs (kg): |

PD05P-XDS-XXX-B 6.28 (2.85) PD05P-XES-XXX-B 6.67 (3.03) PD05P-XKS-XXX-B 6.78 (3.08) PD05P-XLS-XXX-B 7.24 (3.28) PD05P-XPS-XXX-B 5.21 (2.36) PD05P-XRS-XXX-B 5.44 (2.47) Note: PE05P-XXS-XXX-B0S, subtract 0.42 (0.19) |

| Maximum dry suction lift ft (m): | 7.9 (2.4) PTFE fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 71.0 |

Air Line Connection

Air Line Connection

| Pump Model PD05P-AXS-XXX-B |

“A” Material Inlet 1/2 - 14 NPTF-1 |

PD05P-AXS-XXX-B |

“B” Material Outlet 1/2 - 14 NPTF-1 |

| Pump Model PD05P-BXS-XXX-B |

“A” Material Inlet Rp 1/2 (1/2 - 14 BSP, parallel) |

PD05P-BXS-XXX-B |

“B” Material Outlet Rp 1/2 (1/2 - 14 BSP, parallel) |

PE05P-APS-PAA-B0S

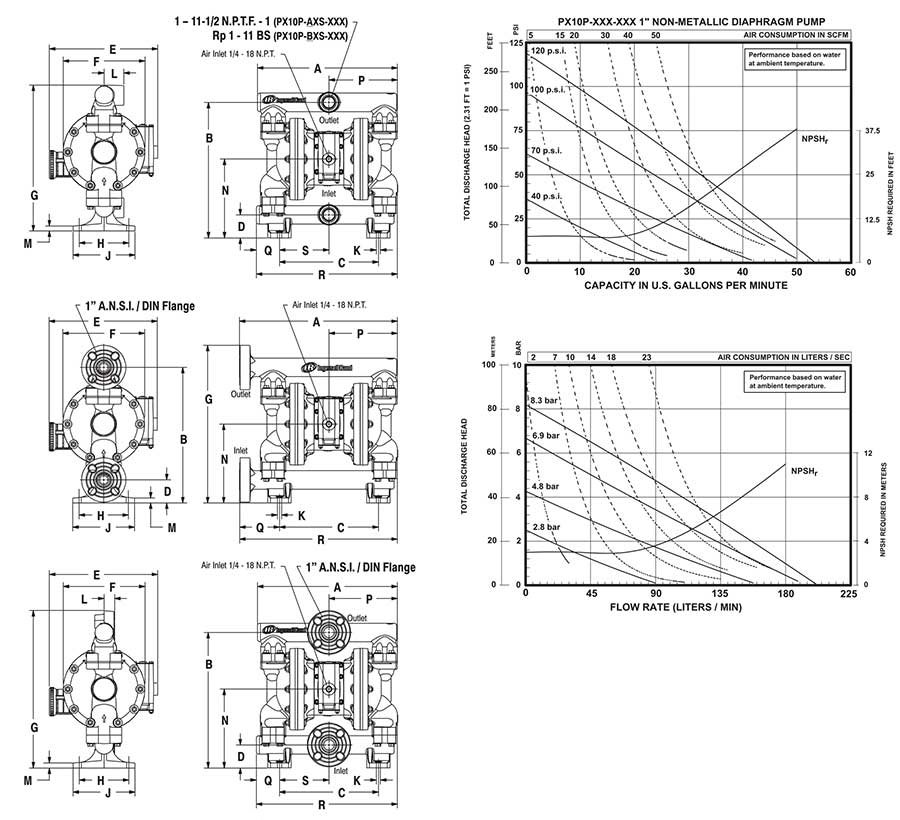

PE05P-APS-PAA-B0S | Ratio: | 1:1 |

| Maximum GPM (LPM): | 53 (200) |

| Displacement per cycle Gallons (Liters): | 0.226 (.86) |

| Air Inlet (Female): | 1/4 - 18 N.P.T |

| Fluid Inlet: | 1 - 11-1/2 N.P.T.F., Rp1(1-11 BSP) 1" A.N.S.I./DIN flange (side or center) |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in.(mm): | 1/8" (3.2) |

| Weight lbs (kg): |

Polypropylene, Threaded Port 19.35 (8.78) Polypropylene, Center Ported 19.59 (8.89) Polypropylene, Side Ported 19.87 (9.01) PVDF, Threaded Port 25.83 (11.72) PVDF, Center Ported 26.72 (12.12) PVDF, Side Ported 27.15 (12.32) |

| Maximum dry suction lift ft(m) : | 19 (5.7) Elastomer fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 79.7 |

Air Line Connection

Air Line Connection  Flange Connection Kit

Flange Connection Kit

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 123 (465) |

| Displacement per cycle Gallons (Liters): | 0.617 (2.34) |

| Air Inlet (Female): | 1/2 - 14 N.P.T |

| Fluid Inlet: | 1-1/2" A.N.S.I./DIN flange (side or center) |

| Fluid Outlet: | 1-1/2" A.N.S.I./DIN flange (side or center) |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in. (mm): | 1/4" (6.4) |

| Weight lbs (kg): |

Polypropylene, Side Ported 42.6 (19.3) PVDF, Side Ported 63.9 (29) Polypropylene, Center Ported 42.3 (19.2) PVDF, Center Ported 55.9 (25.3) |

| Maximum dry suction lift ft (m) : | 14 (4.2) Elastomer fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 81.0 |

Air Line Connection

Air Line Connection  Flange Connection Kit

Flange Connection Kit

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 184 (696) |

| Displacement per cycle Gallons (Liters): | 1.4 (5.3) |

| Air Inlet (Female): | 3/4 - 14 N.P.T |

| Fluid Inlet: | 2" A.N.S.I./DIN flange (side) |

| Fluid Outlet: | 2" A.N.S.I./DIN flange (side) |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in. (mm): | 1/4" (6.4) |

| Weight lbs (kg): | Polypropylene 85.3 (38.7) PVDF 110.9 (50.3) |

| Maximum dry suction lift ft (m): | 14 (4.2) Elastomer fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 85.0 |

67323 Continuous Duty Muffler

67323 Continuous Duty Muffler

67341-E20N Flange Connection Kit

67341-E20N Flange Connection Kit

|

|||||

| Models: | 1/2" | 1" | 1-1/2" | 2" | 3" |

| Maximum Flow GPM (LPM) |

12 (45.4) |

52 (197) |

123 (465) |

172 (651) |

275 (1,041) |

| Maximum Discharge Pressure PSI (BAR) |

100 (6.9) |

120 (8.3) |

120 (8.3) |

120 (8.3) |

120 (8.3) |

| Fluid Ports Inlet/Outlet (BSP) |

3/8 - 18 NPTF-1 Rp 3/8 (3/8-19 BSP Parallel) (Side or Center) |

1-11-1/2" NPT Rp1(1-11 BSP) (Side or Center) |

1-1/2 - 11-1/2 NPTF Rp1-1/2(1-1/2 -11 BSP) (Side or Center) 1-1/2 ANSI/DIN (SS only/Center) |

2" NPTF Rp2(2-11 BSP) (Side or Center) 2" ANSI Flange with 2" pipe tap (SS only/Center) |

3" NPTF Rp3(3-11 BSP) (Center) |

| Materials of Construction |

Aluminum Stainless Steel |

Aluminum Cast Iron Stainless Steel Hastelloy® |

Aluminum Cast Iron Stainless Steel Hastelloy |

Aluminum Cast Iron Stainless Steel Hastelloy |

Aluminum Cast Iron Stainless Steel Hastelloy |

| Pump Weight lbs. (Kg.) |

10.36 (4.7) AL/AL Motor 16.57 (7.52) SS/AL Motor 8.04 (3.65) AL/Poly Motor 14.25 (6.46) SS/Poly Motor |

20.7 (9.4) Alum. 35.2 (16.0) CI 38.2 (17.3) SS 39.6 (18) Hastelloy add 4.65 (2.11) for Alum. air motor, add 11.09 (5.03) for SS air motor |

37.7 (17.1) Alum. 73.2 (33.2) CI 61.2 (27.8) SS 86.9 (39.4) Hastelloy add 3.08 (1.40) for Alum. air motor, add 14.39 (6.53) for SS air motor |

64 (29) Alum. 133 (60) CI 122 (55.3) SS Threaded 114 (51.7) SS Flange 122 (55.3) Hastelloy add 34 (15) for CI or SS air motor |

113 (51.3) Alum. 197 (89.4) CI 203 (92.1) SS 203 (92.1) Hastelloy add 40 (18.1) for SS air motor |

| Maximum Solids inches (mm) |

3/32" (2.4) | 1/8" (3.32) | 1/4" (6.4) | 1/4" (6.4) | 3/8” (9.5) |

| Maximum Dry Suction Lift ft. (m)( |

9.1 (2.8) (PTFE Fitted) |

19 (5.7) (Elastomeric Fitted) |

14 (4.2) (Elastomeric Fitted) |

19 (5.7) (Elastomeric Fitted) |

19 (5.7) (Elastomeric Fitted) |

| Recommended Filter/Regulator Air Line Kit |

P29122-600 66073-1 |

P29221-610 66073-2 |

P29241-610 66084-1 |

P29351-600 66109 |

P29351-600 66109 |

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 12 (45.4) |

| Displacement per cycle Gallons (Liters): | 0.039 (.15) |

| Air Inlet (Female): | 1/4 -18 P.T.F. SAE SHORT |

| Fluid Inlet/Outlet: | 1/2 - 14 N.P.T.F. -1 Rp 1/2(1/2 - 14 BSP, parallel) |

| Max. operating pressure psi (bar): | 100 (6.9) |

| Suspended solids max. dia. in. (mm): | 3/32" (2.4) |

| Weight lbs (kg): |

PD05A-XAS-XXX-B 10.36 (4.7) PD05A-XSS-XXX-B 16.57 (7.52) PD05R-XAS-XXX-B 8.04 (3.65) PD05R-XSS-XXX-B 14.25 (6.46) |

| Maximum dry suction lift ft (m): | 9.1 (2.8) PTFE fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 71.1 |

Air Line Connection

Air Line Connection

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 52 (197) |

| Displacement per cycle Gallons (Liters): | 0.232 (.88) |

| Air Inlet (Female): | 1/4 - 18 N.P.T |

| Fluid Inlet: | 1 - 11-1/2 N.P.T.F.-1, Rp1(1-11 BSP) |

| Fluid Outlet: | 1 - 11-1/2 N.P.T.F., Rp1(1-11 BSP) |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in. (mm): | 1/8" (3.3) |

| Weight lbs (kg): |

PX10R-XAX-XXX 20.7 (9.4) PX10R-XCX-XXX 35.2 (16.0) PX10R-XHX-XXX 39.6 (18.0) PX10R-XSX-XXX 38.2 (17.3) Note: Add 4.65 lbs (2.11 kg) for aluminum air motor Add 11.09 lbs (5.03 kg) for stainless steel air motor |

| Maximum dry suction lift ft(m): | 19 (5.7) Elastomer fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 79.7 |

Air Line Connection

Air Line Connection

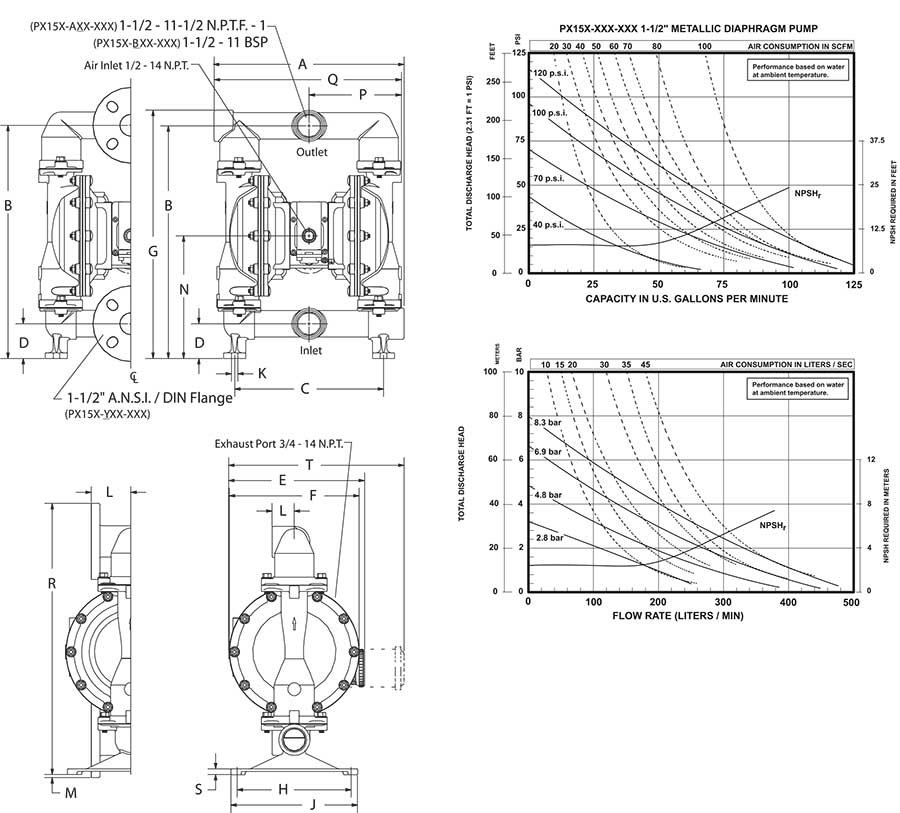

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 123 (465) |

| Displacement per cycle Gallons (Liters): | 0.617 (2.34) |

| Air Inlet (Female): | 1/2 - 14 N.P.T. |

| Fluid Inlet: | 1-1/2" - 11-1/2 N.P.T.F.-1, Rp1-1/2(1-1/2-11 BSP) 1-1/2" A.N.S.I./DIN flange |

| Fluid Outlet: | 1-1/2" - 11-1/2 N.P.T.F.-1, Rp1-1/2(1-1/2-11 BSP) 1-1/2" A.N.S.I./DIN flange |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in.(mm): | 1/4" (6.4) |

| Weight lbs (kg): |

PX15R-XAX-XXX 37.7 (17.1) PX15R-XCX-XXX 73.2 (33.2) PX15R-XSX-XXX 61.2 (27.8) PX15R-XHX-XXX 86.9 (39.4) Note: add 3.08 lbs (1.4 kg) for aluminum air motor section add 14.39 lbs (6.53 kg) for stainless steel air motor section |

| Maximum dry suction lift ft(m): | 14 (4.2) Elastomer fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 50 | 81.0 |

67174-15 Screened Inlet

67174-15 Screened Inlet

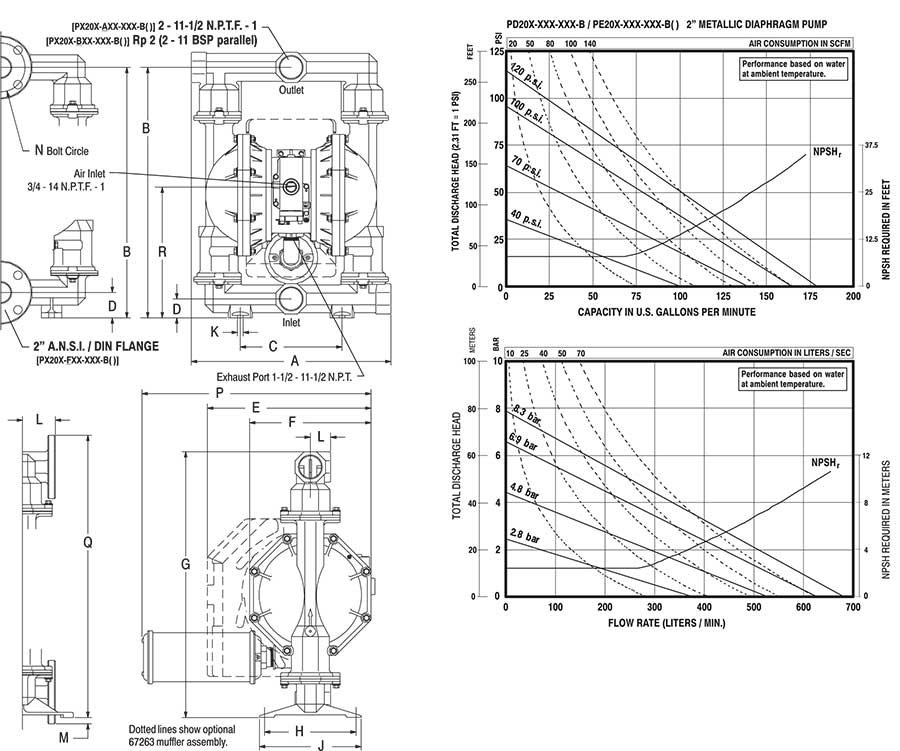

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 172 (651) |

| Displacement per cycle: @ 100 psi Gallons (Liters) |

1.4 (5.3) |

| Air Inlet (Female): | 3/4 - 14 N.P.T.F.-1 |

| Fluid Inlet/Outlet (Female): |

PX20X-AXX-XXX-B( ) 2 - 11-1/2 N.P.T.F.-1 PX20X-BXX-XXX-B( ) Rp 2 (2 - 11 BSP parallel) PX20X-FXX-XXX-B( ) 2" A.N.S.I./DIN Flange |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in. (mm): | 1/4" (6.4) |

| Maximum dry suction liftft (m): | 14 (4.2) Elastomer fitted |

| Weight lbs (kg): |

| Air Motor | Connection | Wetted | Pump Wgt | |

| PD20A | AL AL AL AL AL AL |

Thread Thread Thread Thread Flange Flange |

AL CI H SS H SS |

91.4(41.5) 147.4 (66.9) 155 (70.3) 149.8 (68) 162.2 (73.6) 162.2 (73.6) |

| PD20R≠ | Poly Poly Poly Poly Poly |

Thread Thread Thread Flange Flange |

CI H SS H SS |

165 (74.8) 154 (69.9) 154 (69.9) 146 (66.2) 146 (66.2) |

| Air Motor | Connection | Wetted | Pump Wgt | |

| PD20S | SS SS SS SS SS SS |

Thread Thread Thread Thread Flange Flange |

AL CI H SS H SS |

120.3 (54.6) 176.3 (80) 183.9 (83.4) 178.7 (81.1) 191.1 (86.7) 191.1 (86.7) |

AL-Aluminum, CI-Cast Iron, H-Hastelloy, SS-Stainless Steel

| PSI | Cycles / Min | db(A) |

| 70 | 50 | 85.0 |

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 275 (1041) |

| Displacement per cycle: @ 100 psi Gallons (Liters) |

2.8 (10.6) |

| Air Inlet: (Female) | 3/4 - 14 N.P.T.F. - 1 |

| Fluid Inlet / Outlet (Female): | 3" - 8 N.P.T.F. - 1 Rp 3 (3 - 11 BSP parallel) |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in. (mm): | 3/8 (9.5) |

| Weight lbs (kg): |

PX30A-XAX-XXX-C 129.5 (58.8) PX30A-XCX-XXX-C 216.6 (98.2) PX30A-XSX-XXX-C 228.8 (103.8) PX30A-XHX-XXX-C 249.8 (113.3) PX30R-XCX-XXX-C 242.3 (109.9) PX30R-XSX-XXX-C 253.3 (114.9) Note: Add 40 lbs (18.2 kg) for stainless steel air motor section |

| Maximum dry suction lift ft (m): | 14 (4.2) Elastomer fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 50 | 83.0 |

67263 Continuous Duty Muffler

67263 Continuous Duty Muffler

67174-30 Screened Inlet

67174-30 Screened Inlet

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 172 (651) |

| Displacement per cycle: @ 100 psi Gallons (Liters) |

1.4 (5.3) |

| Air Inlet (Female): | 3/4 - 14 N.P.T.F.-1 |

| Fluid Inlet/Outlet (Female): | PF20X-AXX-XXX-B 2 - 11-1/2 N.P.T.F.-1 PF20X-BXX-XXX-B Rp 2 (2 - 11 BSP parallel) |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in. (mm): | 2" (51) |

| Maximum dry suction liftft (m): | 14 (4.2) Elastomer fitted |

| Weight lbs (kg): |

PF20X-XAX-SXX-B 74 (34) PF20X-XCX-SXX-B 161 (73) PF20X-XSX-SXX-B 188 (85) |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 85.0 |

66109 Air Line Connection

66109 Air Line Connection

67263 Continuous Duty Muffler

67263 Continuous Duty Muffler

| Ratio: | 1:1 |

| Maximum GPM (LPM): | 60 (227.1) |

| Displacement per cycle Gallons (Liters): | 0.234 (.89) |

| Air Inlet (Female): | 1/2 - 14 N.P.T |

| Fluid Inlet: | 1-1/2 - 11-1/2 N.P.T.F - 1 |

| Fluid Outlet: | 1-1/4 - 11-1/2 N.P.T.F. - 1 |

| Max. operating pressure psi (bar): | 120 (8.3) |

| Suspended solids max. dia. in. (mm): | 1/8" (3.2) |

| Weight lbs (kg): | PW10A-XXX-XXX 26.2 (11.9) |

| Maximum dry suction lift ft (m): | 19 (5.8) Elastomer fitted |

| Sound Level: |

| PSI | Cycles / Min | db(A) |

| 70 | 60 | 79.7 |

| Port: | 2" and 3" |

| Material: | Aluminum and Stainless Steel |

| Max. operating pressure psi (bar): | 100 (6.9) |

| Suspended solids max. dia. in. (mm): |

1/4" (6.4) PP20A Models 3/8" (9.5) PP30A Models |

| Weight: lbs (kg) |

PP20A-XAX-AAA 99.4 (45.1) PP20A-XSX-AAA 157.8 (71.6) P30A-XAX-AAA 137.5 (62.4) PP30A-XSX-AAA 236.8 (107.4) |

Air Line

Air Line

Ratio: |

PM05X-X-X-A02 (1/2") 1:1 |

PM10X-X-X-A02 (1") 1:1 |

PM15X-X-X-A02 (1-1/2") 1:1 |

PM20X-X-X-B02 (2")* 1:1 |

PM30X-X-X-C02 (3")* 1:1 |

| Maximum GPM (lpm): | 13.0 (49.2) | 52.2 (197.6) | 123 (465.6) | 172 (651) | 275 (1041) |

| Displacement per Cycle GPM (lpm): |

0.040 (.15) | .232 (.88) | .617 (2.34) | 1.4 (5.3) | 2.8 (10.6) |

| Air Inlet (Female): | 1/4 - 18 N.P.T | 1/4 - 18 N.P.T. | 1/2 - 14 N.P.T | 3/4 - 14 N.P.T.F.-1 | 3/4 - 14 N.P.T |

| Fluid Inlet: | 1-1/2" Tri-Clamp | 1-1/2" Tri-Clamp | 2" Tri-Clamp | 2-1/2" Tri-Clamp | 3" Tri-Clamp |

| Fluid Outlet | 1-1/2" Tri-Clamp | 1-1/2" Tri-Clamp | 2" Tri-Clamp | 2-1/2" Tri-Clamp | 3" Tri-Clamp |

| Max. Operating Pressure: PSI (bar) |

100 (6.9) | 120 (8.3) | 120 (8.3) | 120 (8.3) | 120 (8.3) |

| Suspended solids in.(mm): | 3/32" (2.4) | 1/8" (3.3) | 1/4" (6.4) | 1/4" (6.5) | 3/8" (9.5) |

| Weight lbs (kg.): | 14.75 (6.7) | PM10A-CSS-X-A02 44.3 (20.1) PM10R-CSS-X-A02 38.2 (17.3) PM10S-CSS-X-A02 51.1 (23.2) |

PM15A-CSS-X-A02 61.9 (28.1) PM15R-CSS-X-A02 60.3 (27.3) PM15S-CSS-X-A02 77.9 (35.3) |

PM20A-CSS-X-B02 142.8(64.8) PM20R-CSS-X-B02 157.4(71.4) PM20S-CSS-X-B02 171.7(77.9) |

PM30A-CSS-X-C02 227.5(103.2) PM30R-CSS-X-C02 253.3(114.9) PM30S-CSS-X-C02 267.2(121.2 |

** All Stainless Steel is electro-polished/passivated

P237A1

P237A1 | Maximum Flow GPM (LPM): | 200 (757) P237AX-EU 230 (870.5) P35AX-EU |

| Air Inlet (Female): | 3/4 -14 N.P.T. (P237AX-EU) 1 - 11-1/2 N.P.T. (P35A1-EU) |

| Fluid Inlet: | Screened Inlet |

| Fluid Outlet: | 2" N.P.T.F. P35A1-EU 2-1/2" N.P.T.F. P237A1-EU 2-1/2" BSP P237A3-EU |

| Max. operating pressure psi (bar): | 90 (6.2) |

| Air Consumption in CFM: | P237AX-EU 100 P35A1-EU 160 |

| Suspended solids max. dia. in. (mm): | 1/4" (6.4) |

| Pump Housing Material: | P237AX-EU Cast Iron P35A1-EU Cast Iron |

| Weight lbs (kg): | P237AX-EU 48 (21.8) P35A1-EU 79 (36) |

| Kit Number | Pump Model |

| 66073-1 | PD03P-X, PD05P-X, PD05X-X |

| 66073-2 | PD10P-X, PD10X-X, PE10P-X, PE10X-X, PM10X-X, PW10X-X |

| 66084-1 | PD15P-X, PD15X-X, PE15P-X, PE15X-X, PM15X-X |

| 66109 | PD20P-X, PE20P-X, PD20X-X-B, PF20X-X-B,PP20X-X-X, PM20X-X-X-B02, PD30X-X-C,PD03R-X-C, PP30A-X-X, PM30X-X-X-C02 |

Air Line

Air Line

| Model Number |

Description | Pumps Used With |

N.P.T Inlet |

Gauge Ports |

Max. Inlet PSI |

Pressure Range |

Max. CFM |

Micron Element |

Size L x W |

| MOD 1000 | |||||||||

| P29122-600 | Filter / Reg w/gauge |

1/4", 3/8", and 1/2"(Dia.) |

1/4 | 1/8 | 150 | 0-125 | 12 | 20 | 6.0 x 2.0 |

| MOD 2000 | |||||||||

| P29221-610 | Filter / Reg. w/gauge |

1/2", 1" Models | 1/4 | 1/4 | 175 | 0-125 | 93 | 40 | 9.5 x 2.6 |

| P29231-610 | Filter / Reg. w/gauge |

3:1 (Dia.) | 3/8 | 1/4 | 175 | 0-125 | 135 | 40 | 9.5 x 2.6 |

| P29241-610 | Filter / Reg. w/gauge |

1-1/2" Models | 1/2 | 1/4 | 175 | 0-125 | 140 | 40 | 9.5 x 2.6 |

| MOD 3000 | |||||||||

| P29351-600 | Filter / Reg. w/gauge and bracket |

2" & 3" Models | 3/4 | 1/4 | 170 | 0-170 | 300 | 40 | 10.3 x 4.3 |

| Pulsation Dampener Type: | Non-Metallic / Automatic |

| Material: | See model description chart |

| Weight lbs (kg): |

Polypropylene 8.4 (3.8) Conductive Acetal 8.6 (3.9) PVDF 9.0 (4.1) |

| Material Inlet/Outlet: | SB10X-AXX 1" - 11-1/2 N.P.T. (Female) (Both are available) SB10X-BXX Rp1(1- 11 BSP) |

| Air Inlet | 3/8 - 18 N.P.T.F.-1 (Male) (Standard) |

| Maximum Air Inlet Pressure psi (bar): | 100 (6.9) |

| Maximum Material Inlet Pressure psi (bar): | 100 (6.9) |

| Maximum Temperature Limits: |

Polypropylene 35° F - 150° F (+1.6° C - 66° C) Conductive Acetal 10° F - 180° F (-12° C - 82° C) PVDF 10° F - 200° F (-12° C - 93° C) |

| Maximum Fluid Volume: | 57 In.3 (0.931 lit) |

| Pulsation Dampener Type: | Metallic / Automatic |

| Material: | See model description chart |

| Weight lbs (kg): |

Aluminum (fluid cap) 29 (13.2) Cast Iron (fluid cap) 70 (31.8) Stainless St. (fluid cap)71 (32.2) |

| Material Inlet/Outlet: | SB20X-AXX-X 2" -11-1/2 N.P.T.F -1 SB20X-BXX-X Rp 2(2-11 BSP) |

| Air Inlet: | 3/4" - 14 N.P.T. (female) |

| Max. Air Inlet Pressure psi (bar): | 120 (8.3) |

| Max. Material Inlet Pressure psi (bar): | 120 (8.3) |

| Maximum Temperature Limits: |

EPR -60° - 280°F (-51° - 138°C) Nitrile 10° - 180°F (-12° - 82°C) Santoprene -40° - 225°F (-40° - 107°C) PTFE 40° - 225°F (4° - 107°C) Viton -40° - 350°F (-40° - 177°C) |

| Maximum Fluid Volume: | 159 in.3 (2.61 lit.) |

| Pulsation Dampener Type: | Metallic / Automatic |

| Material: | See model description chart |

| Weight lbs (kg): | Aluminum (fluid cap) 41 (18.6) Cast Iron (fluid cap) 94 (42.6) Stain. Steel (fluid cap) 96 (43.5) |

| Material Inlet/Outlet: | SB30X-AXX-X 3" - 8 N.P.T.-1 SB30X-BXX-X Rp 3(3-11 BSP) |

| Air Inlet: | 3/4" - 14 N.P.T. (female) |

| Maximum Air Inlet Pressure psi (bar): | 120 (8.3) |

| Maximum Air Inlet Pressure psi (bar): | 120 (8.3) |

| Maximum Temperature Limits: |

EPR -60° - 280°F (-51° - 138°C) Nitrile 10° - 180°F (-12° - 82°C) Santoprene -40° - 225°F (-40° - 107°C) PTFE 40° - 225°F (4° - 107°C) Viton -40° - 350°F (-40° - 177°C) |

| Maximum Fluid Volume: | 509 in.3 (8.34 lit.) |

| Description | Model Number | Used With |

| Drum Cover | 66971(stainless steel) | 1/2" Pump 5-Gallon Container |

| Material Agitator | 651100 651103 |

5-Gallon Container 55-Gallon Container |

| Description | Model Number | Used With |

| Wall Mount Bracket | 76763 (Does Not include mounting hardware) 66100 62133 67142 |

1/2" Pump 1" Pump (Metallic Only) 1-1/2" Pump (Metallic Only) 1" Pump and 3:1 1" Diaphragm Pump |

| Description | Kit | Kit Options | Pump Model |

| Mini Batch Counter Kit | 67337-X 67338-X |

-1 (24 VDC) -2 (120 VAC) -3 (No Coil) -1 (24 VDC) -2 (120 VAC) -3 (No Coil) |

PE10X, PE10P, PD15X, PD15P PE10X, PE10P, PD15X, PD15P PE10X, PE10P, PD15X, PD15P PE20X, PE30X PE20X, PE30X PE20X, PE30X |

| Description | Model Number | Used With |

| Siphon Tubes | 61409 PVC 90° N.P.T.(M) 61412 PVC Straight N.P.T.(M) 65109 (CS) N.P.T.(F) 66568 (SS) N.P.T.(F) 66779 (PVC) N.P.T.(F) |

1/2" (Non-Metallic) 55-Gallon Container 1/2" (Non-Metallic) 55-Gallon Container 1" (Non-Metallic) 55-Gallon Container 1" (Non-Metallic) 55-Gallon Container 1" (Non-Metallic) 55-Gallon Container |

| Description | Model No. | Pump Model |

| Countdown Batcher | 67072 | 3/8", 1/2" and 1" ported pumps |

| Description | Kit | Kit Options | Pump Model |

| Cycle Actuation Kit | 67165-X 67355-X 67357-X |

-1 (24 VDC) -2 (120 VAC) -3 (No Coil) -1 (24 VDC) -2 (120 VAC) -3 (No Coil) -1 (24 VDC) -2 (120 VAC) -3 (No Coil) |

PD03P-X, PD05P-X-B, PD05X-X-B PE10P-X, PE10X-X, PE15-X, PE15X-X PE20X-X |

| Cycle Counter Kit | 67350 67350-1 |

PE10P-X, PE10X-X, PE15P-X,PE15X-X, PE20P-X PE20X-X-B, PE30X-X-C |

|

| Cycle Sensor Kit | 67386 67386 637391 637392 637393 |

PD03P-X, PD05P-X-B, PD05X-X-B, PE20P-X PD10P-X, PE10P-X, PD10E-X, PD10R-X, PE10R-X, PD15P-X, PE15P-X, PD15E-X, PD15R-X, PE15R-X PD20P-X, PE20P-X, PD20R-X-B, PE20R-X-B, PD30R-X-C, PE30R-X-C PD10X-X, PE10X-X, PW10A-X, PD15X-X, PE15X-X PD20X-X-B, PE20X-X-B, PF20X-B, PP20X-X, PD30X-C, PE30X-X-C, PP30X-X |

| Kit | Description |

| 67237 | Diaphragm Failure Detection Kit |

| Pump | Model Number |

| 3/8" | PE03P-X-X-A0S |

| 1/2" | PE05P-X-X-B0S, PE05X-X-X-B0S |

| 1" | PE10P-X-X-A0S, PE10X-X-X-A0S |

| 1-1/2" | PE15P-X-X-A0S, PE15X-X-X-A0S |

| Kit | Pump Number |

| 67360 | PE10P-XX-A0S, PE10XX-X-A0S |

| 67361 | PE15P-XX-A0S, PE15XX-X-A0S |

| SERVICE KITS | ||

| Pump Port Size |

Air Valve Kit |

Fluid Section Kit (Diaphragm Material) |

| 3/8" Non-Metallic | ||

| PD03P, PE03P | 637428 | 637429-XX |

| 1/2" Non-Metallic | ||

| PD05P, PE05P | 637428 | 637427-XX |

| PM05P | 637141 | 637140-XX |

| 1/2" Metallic | ||

| PD05A, PE05A, PD05R | 637428 | 637427-XX |

| PE05R | 637428 | 637427-XX |

| 1" Non-Metallic | ||

| PD10P, PE10P, PD10Ev PE10E | 637397 | 637396-XX |

| 1" Metallic | ||

| PD10A, PE10A, PD10R, PE10R, PD10S, PE10S, PM10A, PM10R, PM10S, PW10A | 637397 | 637401-XX |

| 3:1 PH10A-XSS-SST | 637338 | 637339 |

| 1-1/2" Non-Metallic | ||

| PD15P, PE15P, PD15E, PE15E | 637389 | 637391-XX |

| 1-1/2" Metallic | ||

| PD15A, PE15A, PD15R, PE15R, PD15S, PE15S, PM15A, PM15R, PM15S | 637389 | 637375-XX |

| 2" Non-Metallic | ||

| PD20P, PE20P, PD20E, PE20E | 637369 | 637373-XX |

| 2" Metallic | ||

| PD20A, PD20S, PE20A, PE20S, PM20A, PM20S, PP20A | 637421 | 637309-XX |

| PD20R, PD20Y, PD20R, PE20Y, PM20R | 637369 | 637309-XX |

| PF20A, PF20S | 637421 | 637310-XX |

| PF20R, PF20Y | 637369 | 637310-XX |

| 3" Metallic | ||

| PD30A, PE30A, PD30S, PE30S, PP30A, PM30A, PM30S | 637421 | 637303-XX |

| PD30R, PE30R, PM30R | 637369 | 637303-XX |

| 670045-X | 637369 | 637441 |

| AIR LINE KITS | |

| Recommended Air Line Filter/Regulator Units |

Air Line Kit |

| P29122-600 | 66073-1 |

| P29122-600 | 66073-1 |

| P29221-610 | 66073-2 |

| P29122-600 | 66073-1 |

| P29122-600 | 66073-1 |

| P29221-610 | 66073-2 |

| P29221-610 | 66073-2 |

| P29221-310 | 66073-2 |

| P29231-610 | N/A |

| P29241-610 | 66084-1 |

| P29241-610 | 66084-1 |

| P29351-600 | 66109 |

| P29351-600 | 66109 |

| P29351-600 | 66109 |

| P29351-600 | 66109 |

| P29351-600 | 66109 |

| P29351-600 | 66109 |

| P29351-600 | 66109 |

| P29351-600 | 66109 |